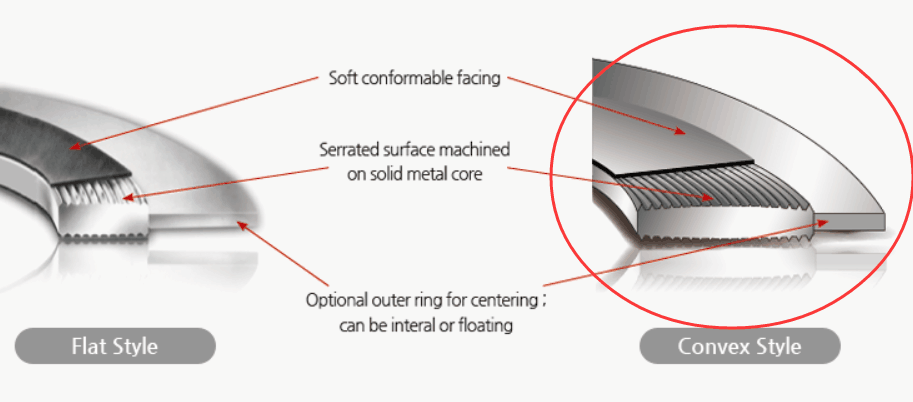

Kammprofile gasket consist of a metal core, generally stainless steel with concentric grooves on both sides. It features excellent anti blowout properties associated with the reliability of a solid meta-to-metal seal combined with soft sealing face to ensure a tighter joint.

>Suitable for a range of chemicals

>Suitable for use in high pressure and high temperature applications

>Can be refurbished and reused

>Can be manufactured to suit standard flange applications and vessels.

>Can be manufactured for use with narrow flanges

Better leak tightness than spiral wound gasket

>Carbon steel, stainless steel, 321, 347, monel 400, inconel, incoloy, nickel, titanium, hastelloy, copper

>Coating materials: Graphite, PTFE, Mica, etc.

Products are manufactured in accordance with all relevant gasket standards to suit flange designations: ASME B16.5, BS1560, ASME B16.47, BS EN1092, DIN, JIS and NF.

|

Temperature Min Max |

-200oC (-328oF) +1,000oC (+1,832oF) |

| Pressure, Max, Bar (PSI) | 414 (6,000) |

| pH range, Room Temperature | 0~14 |

|

Gasket Factors m Y,psi |

4.00 1,000 |

KAXITE Code: KXT 1110-CO

KAXITE Convex Type of Kammprofile Gasket is design for where the main sealing faces of the serrated metal core are slightly convex in profile.

The convex core helps compensate when flange rotation is experienced on bolt up of weaker flanges.